Page 2 of 6

Carb

Posted: 07 Jan 2008, 17:27

by knackeredMk1

Just got a new carb - 33mm PWK. In Japan there are several CRMs running with a 35mm PWK which is supposed to give significantly more peak power than standard 32 mm PE. Most are SuperMotards.

Side by side there is not alot of difference. PWK has 1.5mm external diameter larger inlet and outlet - so no problem with fitting. PWK is also ~135g lighter.

The PWK is 4mm shorter than the PE so I might have to make a spacer.

(Didn't need to in the end.)

The main difference is in the slide shape which apparently gives much improved throttle response. The larger diameter (of the 35mm PWK over the 33mm PWK) would in theory help peak power a little but I went with the smaller diameter (of the 33mm PWK over the 35mm PWK) to try to retain the low end torque.

Air flow is ...........................................................>>>>

Just out of interest the KDX220 has a 33mm PWK whilst the 200 has a 35mm.

Jetting

Posted: 07 Jan 2008, 17:54

by knackeredMk1

I'm turning this into a jetting nightmare

Original is 132 main and 45 pilot

Proposed changes will be - freer breathing airbox, freer breathing air filter, enduro Stan Stephens tune (inc skimming of head), Boysen reeds, DEP silencer, FMF expansion chamber and rebore.

We guestimated on 155 main and 50 pilot but no doubt it will need some fine tuning

Water Pump Shaft

Posted: 17 Jan 2008, 12:27

by knackeredMk1

Honda have no more Mk1 water pump shafts. Mk2 shafts fit but you have to change the bearing at the bottom of the shaft as the end is 1mm larger.

Old bearing 19 ext dia, 7mm int dia, 6mm deep - New 19,8,6

Further Clutch Work

Posted: 21 Jan 2008, 18:48

by knackeredMk1

Almost finished machining clutch basket. Some weight reduction to go then just got to balance, bead blast to remove machining marks, and anodise.

Bad News

Posted: 22 Jan 2008, 21:19

by knackeredMk1

I'm afraid to say that whilst doing the final milling on my clutch basket no account was made of the concentricity in changing mounting heads. This resulted in a +/- 0.8mm

error in machining of the slots for the tabs on the clutch plates.

I now pronounce this part of the project as scrap

Re: New Knackered's Project

Posted: 25 Jan 2008, 12:51

by knackeredMk1

It seems that the dividing head I used for the last milling was not accurate in the degrees of turn it gave.

Well I've picked myself off the floor and am just going to get another piece of aluminium (at a discount as the supplier is also gutted

)

Cooling Fan

Posted: 25 Jan 2008, 14:10

by knackeredMk1

Was intrigued by several other forumites (well two in particular

) using fans to cool their engines. I know from past experience that the Mk1 in particular can get quite hot and would probably benefit from some extra cooling in boggy situations. Below is my interpretation of the work that has gone before -

The fan is 120mm 12v computer cooling fan (eBay ~$5.00). M4 stainless threaded bar (eBay - £3.00). Epoxy glue and a small strip of double sided foam.

The fan has 3 wires and 2 speeds. I plan on having it run all the time on silent mode (slow) with a switch to change this to full power when I need it

.

Wheels

Posted: 31 Jan 2008, 16:28

by knackeredMk1

Got some wheels. They come from an XR650. The front is really nice, the rear not so. The rear will need a complete set of bearings, seals and spacers to fit the Mk1's spindles but the size of the bearings might mean they last a bit longer

Clutch Basket Mk2

Posted: 15 Feb 2008, 13:25

by knackeredMk1

Finished the main work on Mk2 version of clutch basket. Tidying up, balancing and anodising to go. Should be much stronger than the cast original and is 11% lighter.

Front Spindles

Posted: 26 Feb 2008, 16:36

by knackeredMk1

I've managed to find a CR125 1989 front axle (US eBay $10). This saves expense in that I do not need to change the bearings and spacers of my front wheels and the whole setup is stronger being 17mm diameter rather than 15mm.

I'm getting rid of the speedo drive as I'm going to get a Vapor setup from Trail Tech to give me speed, water & air temp, etc.

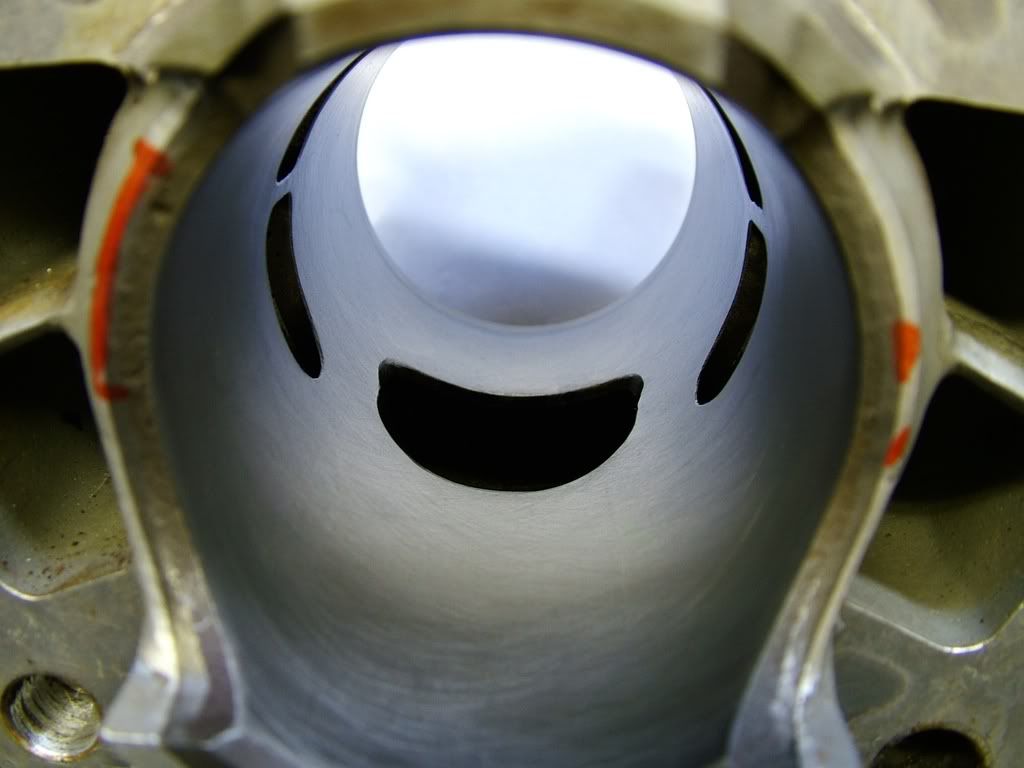

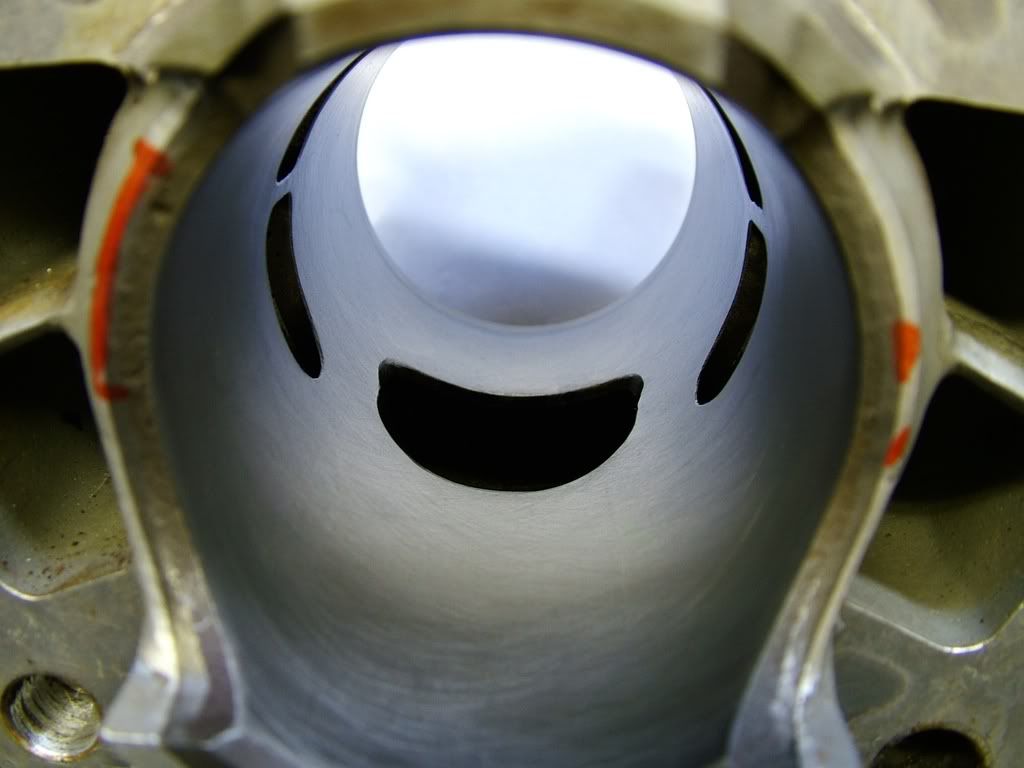

Cylinder

Posted: 27 Feb 2008, 16:22

by knackeredMk1

Got hold of a Mk2 barrel and head. I was going to rebore the original Mk1 and get it tuned by Stan Stephens however the Mk2 barrel has had the transfer ports tidied a bit and the exhaust port widened just a touch (over where the powervalve sits when closed). There is a little more work to do where the red pen marks are but it dosen't need a rebore (I've just honed it). The bore diameter varies from 65.98mm - 66.05mm; so it's on it's first size.

I don't think it is worth taking to the Great Man yet. I think I will just get the head skimmed. (Lots of money saved

)

Mk2 -

Mk1 -

Cylinder Base Profiling

Posted: 28 Feb 2008, 15:29

by knackeredMk1

Finished profiling the aluminium/cast iron junction at the cylinder base and the transfer ports.

Mk2 was actually worse than the Mk1.

Rear Muguard Finished

Posted: 29 Feb 2008, 17:42

by knackeredMk1

Things are moving on and I'm getting closer to 'Rebuild Day'. Should be close to the end of March.

Finished rear mudguard and no. plate etc. Fitted three small white LEDs to light plate under/in the tail light.

Intake

Posted: 01 Mar 2008, 13:22

by knackeredMk1

New intake rubber from carb to crankcase. Mk1 consists of two pieces - one nylon insert (below) that fits in the reed cage and a (perished

) rubber boot that is internally shaped to match the insert. Mk3 is one piece - It has a much smaller internal diameter. I suppose this is to keep the speed of flow of the charge up & partially leads to the increased torque of the Mk3 (Mk2?) over the Mk1?

Rear Disc & Chiain Tensioners

Posted: 03 Mar 2008, 16:53

by knackeredMk1

New rear disk and pads - Made in Argentina, sold in the USA and transported half way round the world for just less than £40. How can it be done

? (Maybe I'll find out

)

Chain adjusters are stainless steel from Germany and designed for an Africa Twin but fit fine. (Jonorow's tip)

Haven't lost the desire to make some carbon bits & bobs - Having trouble making a mould from the original parts